Hi guys

I Own a Carver Onean unfortunately the battery didn’t last long.water was actually leaking out ot the locking mechanism and the battery didn’t show any signs of life.

Was waiting for ever to get a replacement battery from Jon in Onean .

But the company closed instead.

Didn’t want to give up on the board

So with the help of friend.owner of a small factory for E trike and battery packs .we open the carver battery and build a new design 12s1p 60ah 5c cells that can handle the carver motor quite easily.and last much longer

Someone try to build a replacement battery for Onean? As many board out there seems like the board will last and pretty soon there will be no good batteries to run them .

Hello from Greece.

As you describe you found the way to build a new battery for Carver X?!

Where are you from?

My best regards.

Andreas (andreaskrinas@outlook.com)

I wonder how to open the battery without damaging it. And also how to seal it back up perfectly after refurbishment.

What kind of cells were used? Capacity 60Ah with a continuous current load of 130A (5C~300A) at 3.7V, only Li-Pol prismatic cells are considered.

Original Akku Power GmbH Lithium Ion Battery APAQ 12S16P parameters:

Weight: 12KG

Cells: 192=16x12 Samsung INR18650-25R R5 2500mAh

Nominal voltage: 44,4 V (44,4 V/12=3.7V per cell)

Max Power: 5000W

Max. electric discharge: 130 A (12S: 3.2V * 12 = 38.4V, 5000W / 38.4V = 130.2A, 16P: 130.2A / 16 = 8.14A)

Capacity (rated): 1500 Wh/40 Ah

Cycle count: 500 (estimated)(~300)

Charger 15A/50.4V (15A/16=0.9375A Charging Current per cell)

The pack are built based on the cell array of Samsung´s lithium-ion battery with 18650 format, which is widely used on electric cars or power tools.

Samsung INR18650-25R R5

Nominal Capacity: 2500 mAh

Nominal Voltage: 3.6V

Discharge End Voltage: 2.5V

Standard Charging Current: 1.25A

Charging Voltage: 4.20±0.05V

Max. Continuous Discharging Current: 20A

Battery Capacity (Mfg Rated): 2500 mAh

Battery Chemistry: INR - LiNiCoMnO2

Battery function: Rechargeable

Battery Shape Factor: INR 18650

Battery Rated Voltage: 3.6 V

Brand: Samsung

Depth: 18.2 mm

Height: 65 mm

Width: 18.2 mm

Battery cell layout option

Sony / Murata US18650VTC6 3120mAh - 30A (see eu.nkon.nl)

16px12s=192 cells á 3.75€ with VAT (750€ price for 200 pcs)

Capacity 16x3.12=49.92Ah/~1872Wh (25% higher capacity compared to the original cells)

Thank you very much.

Andreas

Coralli Resort Serifos

Have you had any success with the rebuild? I just picked up one of these boards with 2 battery packs and a week apart both batteries won’t take a charge. Assuming is the BMS that has failed I want to open the box and test it. The case seam has separated but I can’t seem to get the case around the terminals to free up. Step one separate case is a bust as of now. It looks super simple inside from what I can tell I just don’t want to break the housing, I have no access to molding plastics without a serious project. Thanks in advance

I think this is a case where the voltage of individual battery cells has dropped by self-discharge below a certain limit (approx. 2.5V) and the BMS then refuses to charge them because it considers them destroyed or too worn out. This may not be true and the remedy is to charge each individual battery cell to at least 2.6V (better 3.0V). I do this by directly attaching the contacts of the 3.6V DC source and the correct cell poles. It only takes a few minutes and the cell voltage will increase from e.g. 0.7V to 2.7.V. This needs to be done for all cells (there are 192 of them) and at least measure them to see if they are in the range acceptable for BMS operation. The BMS will already rebalance the cells to the same voltage when connected to the charger.

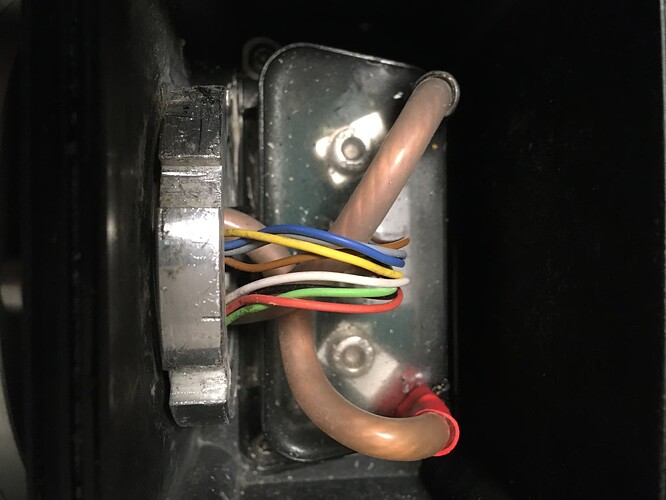

I haven’t opened any batteries yet, but I was thinking of carefully cutting off the bottom of the battery with a few centimeters of edge and after replacing the cells, laminating the walls around the perimeter of the cut to reinforce and seal the cut. The lamination layer must be quite thin as there is not much room in the battery shaft. As a protection against possible water ingress into the battery, I would waterproof the cells with a non-conductive gel (DISTYK TL 04.95DEU ELECTROGEL), which is used, for example, to waterproof the motor contacts. This can be seen after removing the smaller front motor cover. By the way, the spaces under the cover are not watertight at all, but flooded with water.

.

I would be interested in pictures of even a partially disassembled battery. So far I’ve only seen images of the cells of a burnt out battery, but from these I can’t discern the possibilities of the battery disassembly procedure.

Perhaps a solution would be to contact the direct manufacturer of the Onean battery, which is Akku Power Gmbh. This company routinely remanufactures (repass) batteries for cordless tools, so they may be able to remanufacture batteries that they have made themselves. I don’t know at what cost though.

Headquarter

Akku Power GmbH Batterien

Paul-Strähle-Straße 26

D-73614 Schorndorf

Contact:

Phone: +49 7181 97735-0

Fax: +49 7181 97735-29

info@akku-power.com

France

Akku Power France

64/70 rue Rouget de Lisle

92150 Suresnes

Contact:

Phone: +33 1 81 93 82 50

Fax: +33 1 70 24 86 91 gael.legrix@akkupower.com

Czech Republic

Bech Akku Power, baterie s.r.o.

Kozojedy 141

331 42 Kralovice

Contact:

Phone: 373 398 300

Fax: 373 398 259

info@bechakku.cz

Italy

Akku Power Italy

Contact:

Phone: + 39 3483162296

Fax: +49 (0) 7181 97735-29

info@akku-power.com

Spain

Akku Power Iberia

Sallares i Marra, 72-78 Local 2

08203 Sabadell (Barcelona)

Contact:

Phone: +34 93 7125016

Fax: +34 93 7205946

iberia@akku-power.com

Thank you for all of the detail. I took a break so I didn’t break it or throw it. A couple of things. First when I would connect the two leads to the battery from the charger I was able to see the lights tell me how charged it was or wasn’t. That had stopped, but both batteries had leaky tops and one had a crack in the bottom I never noticed and it definitely got saltwater in it. With that being said I checked my charger and the output is supposed to be a 15 amp charger, when I check it not connected I am seeing 28 amps output. I’m not sure this did damage to the module or not. I did take a few pictures of what the battery looks like now and I’m thinking about just cutting the housing off the bottom around the two leads since the case is trash already. Here’s what I have so far.

Well guess not I’m too new so no pictures allowed

Caution leaking batteries can be very dangerous, they can spontaneously combust. I recommend storing them in a safe container. My first two batteries also had cracks, one went dead, the other worked but Onean definitely did not recommend using it.

It could be tons of work to DIY a battery pack.

It’s not time-consuming in the cell selection phase as I believe there are already excellent suggestions. As for the BMS board,it’s also not hard since you can search for it from eBay.

However, it might be a challenge to find a suitable cell holder and nickel plate to store your cells, since usually it’s customized and needs tooling modification. General ones may not fulfill the size and can cause safety issues regarding vibration and drop in the real surfboard test.

Besides, you may also face sealing issues if not a reliable battery enclosure is housing. Overall, I don’t think a DIY battery would be feasible, but good luck with that and respect.

That’s an impressive solution! It’s unfortunate that Onean closed, but it’s great that you and your friend were able to build a new, more durable battery for the Carver. You’re right—many boards might face battery issues as they age, and creating compatible replacements is definitely a smart move. Have you considered sharing the specs or offering this as a replacement option for others with the same problem? It could help a lot of people keep their boards running!

Hi there

Im from Sweden and I have 2 batteries to sell if you are interested!

Hello,

Do you still have the battery, how much would it cost?

Hi I still have them!

100euro each!

Where do you live?

I mean 1000 eur… each

Thanks for the answer!

I live in Hungary.

I don’t need the battery.

I repaired a friend’s battery, but it didn’t work, the BMS is bad and 60 battery cells are also defective.

Can I have an email address? My friend is looking for the details.

Have a nice day! Georg

My emailadress:

Jorgen@fotamera.se

We are going on a vaccation to polen if it can be any closer. To ship those batterys as a privat person is not easy. I did Try once but failed.

//

Jorgen