The fasteners set also includes a magnet coated with some plastic, so the problem of magnet corrosion is also solved. Magnet size is 24x9.9x4.9 mm.

Good to see that there is progress. Important for all their users out there. I doubt however that the fireproof SAVE bag, can be really SAFE. I think it needs more than just such a bag. For any vendor.

Thanks also for sharing the video, but I am wondering if this small section marked in the picture below which is holding together metal and carbon fibre can handle all the force produced by a heavy rider? It seems that the surface is not even and completely aligned?

Finally, I tested my Waydoo Flyer One on the Orlík dam using fasteners (short mast, Explorer wing) and at my current weight of 97 kg I did not notice any problem after driving 5 batteries.

By now having the support elements on both sides and spaced apart by the thickness of the wing and, in addition, the screws tightened together, the rigidity of the support elements has been substantially increased, so that the bending moment of the wing can easily withstand them.

Beginners ATTENTION, use the rash guard otherwise you will rub your belly bloody by lying on the board like me.

Can you share a photo of the inside of the crack, as I know they have an alloy frame inside. I doubt you can break this by natural force maybe bending but not crack…

So I would like to see the inner ally frame…

Kevlar coated board compatible with polystyrene foam version can be purchased for 2500 EUR.

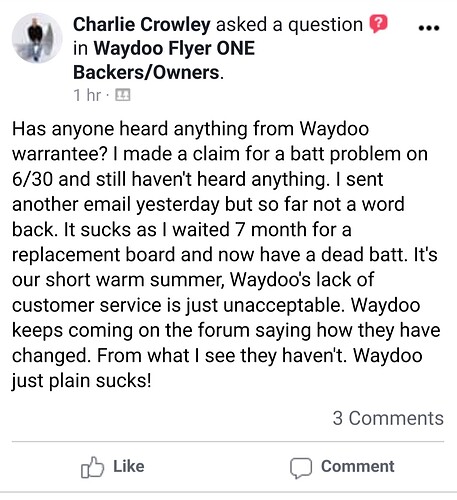

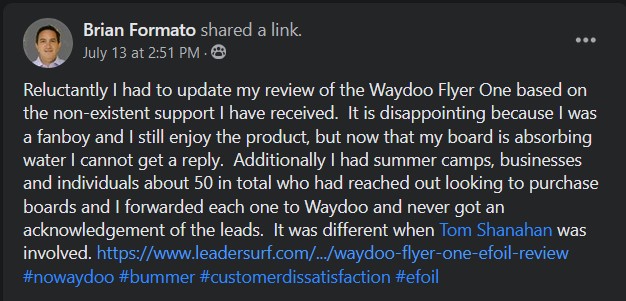

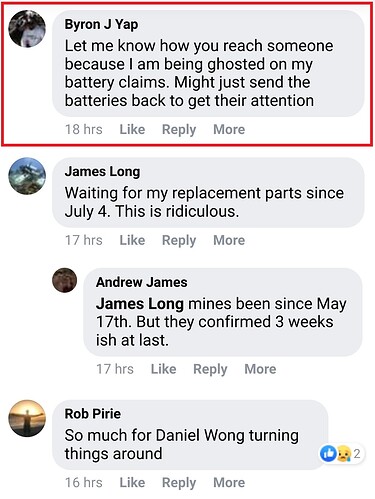

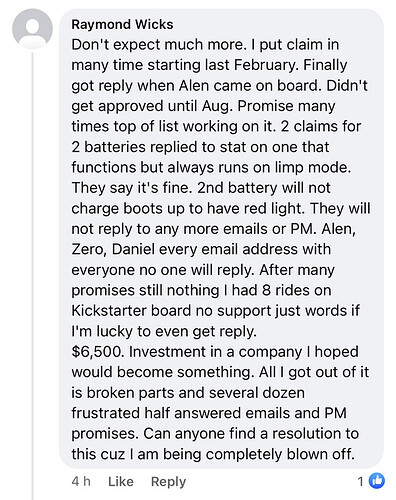

The difference between Elite brand and the brand that cuts the corners is the post sale service and warranty. Here is another victim

It is a sad story, but not surprising. Many people complain why the premium boards are so expensive. But there is a reason.

It is not only the materials and technology. It is the good, reliable and fast customer support which is really expensive.

If you bring a cheaper product to market it highly likely that you get a more support cases. At the same time you have less margin to pay for good support. It’s a vicious circle.

I think you have to differentiate between USA and Europe. It seems to be more reliable here in Europe. And almost all the reports you read seem to have the first version… A Friend had flickering screen in the remote control… did ask for warranty and after sending his data+short video of the problem, he got new remote control sent to Austria on vacation within 4 days… It came from central warehouse in Germany… In my opinion, they have improved a lot in Europe… and since you see more and more on the water after 2 years that speaks as well for a solid company… Basically better than I expected for 6000€

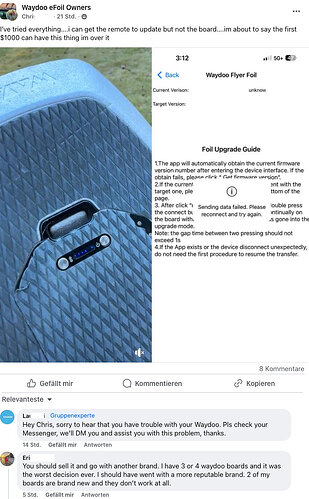

I thought two years later Waydoo would have been able to resolve these issues. According to their Facebook group may be not ![]()

This is clearly an old model, as one can see on the fuselage screws… Don`t know when this photo was taken, but it is the old Fuselage/Mast…

Yes it can be fixed, but if you are still on warranty I´m sure you will get replacement;-)

I carbonized my board to prevent something similar.

The first layer is kevlar.

Second layer is carbon.

It is not a professional implementation, but it fulfils its purpose - prolonging the mechanical life of the board. It does have a downside - it holds water inside and I have to dry the board outside. It puddles underneath.

From Facebook:

Word of warning if you buy a new Waydoo, double check the trigger before you head in. I lost my board right after buying it because of a malformed trigger. Could be a life threatening issue for a new rider.

I have had problems with one of my batteries due to poor placement of the magnet sensor inside the battery. Lining up the original magnet didn’t help much. After falling off the board or moving the board wildly, the connection would often break and it was quite a problem to re-establish it on the water. Once I had to push the board 2km to the shore.

For this season I have radically solved it. Using a scalpel I cut a hole for the second magnet and used a screwdriver to break the hole. I used the magnet that came with the fasteners. The magnet is held in the hole with adhesive velcro. The location of the original magnet is highlighted in the photo by the ferromagnetic dust on the yellow tape that holds it in place. The original sticker doesn’t hold much anymore. The polarity of the magnet placement is important. Both magnets must point inside the battery hole with the pole repelling each other.

Since placing the second magnet, my battery problems have disappeared. It’s an effective and workable solution.

Seems that Waydoo is still struggling with quality issues. I found this today on Facebook:

I don’t understand why they are focusing on new features such like wheels, auto balancing, handlebars and so on rather to finally make their product rock solid.

These features are all nice to have, but at the end of the day it just needs to work properly.

Just my 2 cents.

It is just easier to add some cheap plastic parts or chips rather than replacing all components with high quality engineering parts.

This discussion goes on since years: “You get what you pay for”. There is a reason why the premium eFoils have a much higher price tag: Good engineering, better quality parts and great support (at least in most of the cases) …